Add to Cart

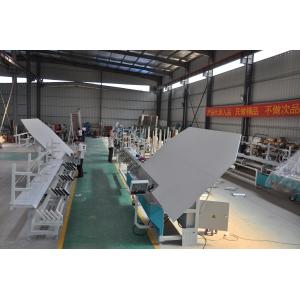

Automatic spacer bending machine is a special equipment for making aluminum frames of insulating glass

Application

Automatic spacer bending machine is a special equipment for making aluminum frames

of insulating glass, which replaces the traditional fabrication technology. This equipment

can make a variety of convex polygonal aluminum frames by one aluminum strip in one

time, thus strengthening the strength of the aluminum frame, making the sealing effect of

the insulating glass more better.

Technical data

| Max.bending size | 2000mm*2000mm (2500mm*2500mm) |

| Min.bending size | 250mm*200mm |

| Aluminum spacer width | 5.5-27mm |

| Dimensional error | ±0.5mm |

| Angle error | ±1º |

| Processing speed | ≤26s |

| Air supply | ≥0.65MPa |

| Total power | AC220/380V 50Hz 2.5KW |

| Dimension | 10500mm*2200mm*2600mm |

Equipment details

Bend shaped spacer frames continuously

JINAN KATION TRADING CO.,LTD.

Founded in 2009, Kation-Tech specializes in R&D, production and sales of Insulating glass

machinery and related auxiliary equipment for the glass deep processing industry and the door

and window construction industry

Has the professional processing basis of insulating glass machinery, aluminum-plastic windows &

doors machinery and the related auxiliary materials, etc. In this way, we provide the most comprehensive

glass processing solution and windows & doors solution for domestic and foreign customers well

Until 2019, we exported glass machines and materials to America, South America, Europe,

the Middle East, India and so on, nearly 30 countries and regions. We have established a perfect

international business relationship with 10 powerful agents and made an endeavor together to build

a famous international brand to the world. Kation-Tech

FAQ

Q: What is the system of Kation’s after sale service?

A: Kation has its own special system for the service, we make a “tree of knowledge”for guiding customer to find

the usual problem and the answer when customers meet.

Q: What is the details of the after sale service?

A: Step1: Notice before installation

Step2 : Confirm before installation

Step3: On-site installation

Step4: On-site debugging

Step5: On-site training

Step6: Client sign

Step7: On-line service

Step8: Technical service

More details please search www.lijiang-glass.com