Add to Cart

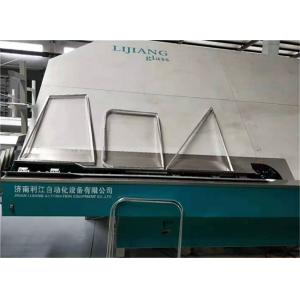

Double Glazing Glass Automatic Aluminum Spacers Bending Machine

When coated with Low-E film, an insulating gully protects against radiation. The butt is made of two or more float glasses with an aluminum frame filled with an argon gas desiccant. Primary seal (butyl), secondary seal (polysulfide or structure) between double glazing and aluminum frame. Double glazing is effective

Features of Automatic Spacer Bending Machine

• 4 or 12 groups of spacer racks

• High working speed Siemens 1200 PLC control system

• Automatically avoid pins during bending and cutting

• Bend the spacer frame continuously

• Automatically cut and feed aluminum spacers

• Aluminum spacers are available in sizes 6A-27A

• Different bending tools for different spacer sizes

• Suspend and reset devices to handle device failures

• Bent aluminum spacer, smooth stainless steel, warm spacer

• USB input function, read Excel format files directly

Detail of Aluminum spacer bending machine

1.German siemens plc control system,touch screen interface.

2.Four or Twelve different spacer size storage units can choose

3.Heavy duty connectors ,convenience and safety for installation and debugging

4. Aluminum spacers are available in different specifications and sizes

5.Support continuous bending , it automatically avoid spacer -connection while bending and cutting

6.The special machine hand device is used to bend big spacer frame

7.Automatic spacer bending machine can bend aluminum spacer /technoform /Alupro /swisspacer/ stainless steel /thermix (optional)

8.USB input function ,it can read the excel data directly

9.Spare parts of all machine have ID code ,convenient for after-sale service

After-sales service of Lijiang glass for automatic aluminum spacer bending machine

I. Warranty: 1 year

Damage to worn parts or equipment due to customer reasons is not covered by the free warranty.

Ⅱ. Lijiang has its own system for after-sales service consisting of three parts.

1. When the LIJIANG equipment arrives at your factory, LIJIANG can send an engineer to your factory for free installation, accommodation, and personnel training. However, you will have to pay for the engineer's round-trip ticket and accommodation.

2. If there is a problem with Lijiang's equipment beyond the warranty period, Lijiang will first provide online and timely technical support. However, if you wish to be an engineer in Lijiang, you will be required to pay the engineer's round-trip ticket and accommodation, and pay $ 150 per day to Lijiang as a service commission.

3. During the warranty period, if there is a problem with Lijiang's equipment, Lijiang will first provide online and timely technical support. However, if the engineer needs to go to your factory repair machine, you will have to pay for the round-trip ticket and accommodation. If the spare is damaged due to Lijiang, Lijiang will prepare it in advance (excluding worn parts).

Note: Before the Lijiang engineer goes to your factory, you must submit your ticket and hotel details in advance. Lijiang will arrange the engineer's itinerary and maintenance items as soon as possible.

Optional functions

• Connect to ERP system

• Drill holes

• Printing code

• Printing label sticker

• Bending shape frame. Using the circle wheel device to bend circle frame or frame with circle corners. Min R60, Max R150, spacer sizes: 6A – 16A). Different sizes of aluminum bars require different size tools

Technical Data of spacer bending machine

| Max. bending size

| 2000mm*2000mm |

| Min. bending size

| 250mm*180mm |

| Aluminum spacer width

| 6A - 27A |

| Spacers racks | 4 Racks |

| Spacer size error

| ±0.5mm |

| Angle error

| ±1° |

| Processing speed

| < 25s (1000mm*1000mm) |

| Air supply

| ≥0.65MPa |

| Voltage | 380V50Hz 3P |

| Total power | 2.5KW |

| Dimension 尺寸 | 10500mm*2200mm*2600mm |