Add to Cart

Common 2500*3500 Insulating Glass Line With Filling Argon Gas

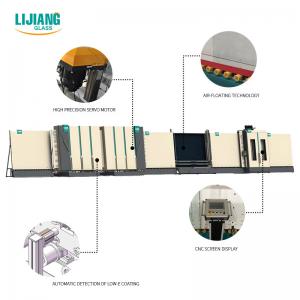

The insulating glass production line is the main equipment for the production of insulating glass products. IG wire has normal wire size 2000*2500 and 2500*3500 IG. The maximum size of argon gas is 2500*3200. LJBZ2535G argon-filled vertical insulating glass cleaning and rolling production line can perform the following functions: glass cleaning machine, aluminum frame installation, double-layer ordinary glass, triple-layer ordinary glass, special shape. LJBZ2535G production line is special equipment for producing aluminum strip insulating glass. It has the advantages of Siemens servo motor, high efficiency, reliable performance and convenient maintenance.

LJBZ2535G vertical insulating glass production line includes:

1. LJBZ2535G loading section

2. LJBZ2535G washing&drying section

3. LJBZ2535G discharging section

4. LJBZ2535G inspection and frame installation section

5. LJBZ2535G flat press lading section

6. LJBZ2535G glass pressing and filling argon gas section

7. LJBZ2535G flat press discharging section

Parameters :

Details introduce of the LJBZ2535G

• 01 transfer section

Coating detection mechanism, automatic detection of offline Low-e film

• 02 washing machine

Main feature:

• Use 6 soft bristle brushes with 0.1mm bristles to clean low-E glass

• Prewash (optional)

• The new air gap adopts aluminum profile (Duckbill Air Knife), and the size of the air outlet is adjusted by the aluminum profile of the duckbill. It can reduce the number of adjustment screws, ensure that each screw is not loose, and avoid air gap resonance.

• The air knife can automatically adjust the width of the air knife according to the thickness

• Operation box with washing speed display, which can accurately display the washing speed (8-10m)

• Automatic water tank temperature control and water replenishment system

• European silencer system

• Stainless steel

• 03 discharge section

• Storage glass

• 04 Inspection and Installation Section

The new structure of this section is replaced by an in-line lifting beam structure (double beam). Easy to inspect and wipe the glass

• 05 Transmission Section

• Automatic measurement of glass thickness. It can be used according to actual needs during work.

• 06 Press and complete the section

Main feature:

• Extra long insulating glass (2500mm x 3500mm) can be compressed twice

• The glass is conveyed by conveyor belt, and the glass is pressed by servo motor

• Platen can be opened for easy maintenance

• Adjustable platen structure, long service life

• Auto-filling with argon gas, the sealing effect is remarkable, and the argon gas content is higher

• Use trace seal method to define areas to fill different sizes of glass to reduce argon loss

• Can set gas value and display inflation process on touch screen

• Fast response sensor for continuous monitoring of the aeration process

• Gas concentration can reach more than 90%

• No need to drill holes in the bulkhead

• Standard gas is argon

• 07 discharge section

• Storage glass

• Can be connected to a sealer

| NAME | ORIGIN | BRAND |

| Servo motor | Germany | SIEMENS |

| PLC | Germany | SIEMENS |

| Low voltage electrical appliance | Germany | SIEMENS |

| Frequency converter | Germany | SIEMENS |

| Transfer motor | Taiwan | LINHAI |

| Brush motor | Taiwan | LINHAI |

| Water pump | China | LINGXIAO |

| Guide | Taiwan | HIWIN |

| Pneumatic Components | Taiwan | AIRTAC |

| Electric gauge | China | MIRAN |

| Photoelectric switch | Germany | SICK |

| Micro Switch | Taiwan | TEND |

| Button and indicator light | France | SCHNEIDER |

| touch screen | Taiwan | WEINVIEW |

| Intermediate relay | Japan | OMRON |

| IG line with gas filling online | ||